Highly efficient adsorption: the fluffy structure of the nylon fiber provides a larger surface area, which increases the adsorption capacity of the sample.

Good release: In the subsequent laboratory processing, the flocked swab can release the adsorbed sample efficiently for testing.

Softness: The softness of the nylon fiber allows the flocked swab to be used without causing discomfort when in contact with skin or mucous membranes.

Reusable: Flocked swabs can be reused multiple times in certain non-medical scenarios and have a long service life.

Sponge Swabs:

Highly absorbent: The high porosity of the sponge allows it to quickly absorb large amounts of liquid samples.

Soft touch: The soft texture of the sponge swab reduces irritation to the sampled person, especially for infants, young children or sensitive people.

Ease of handling: The elasticity of the sponge swab allows it to adapt to differently shaped surfaces during use, improving sampling efficiency.

Sterility: The sterile sponge swabs are made through aseptic technology, which ensures that the sterility is maintained during use and effectively reduces the risk of infection.

Third. Application Scenarios

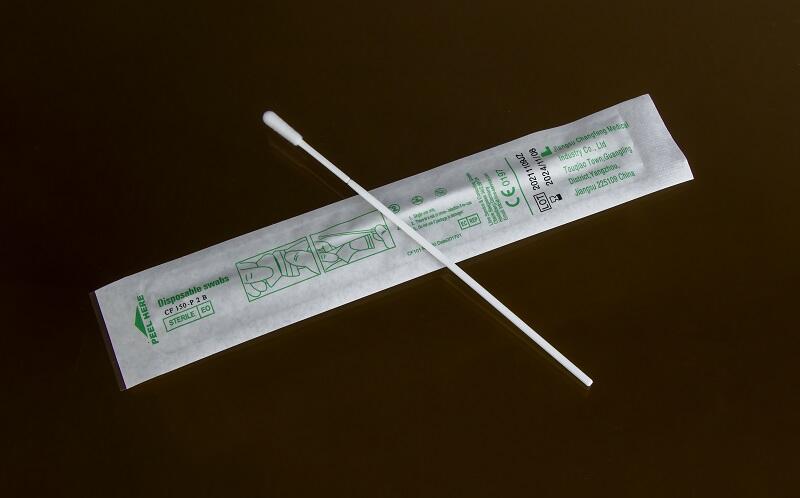

Flocking swabs: Due to its good adsorption and release characteristics, flocking swabs are commonly used for virus and DNA sampling, such as the detection of influenza virus and HPV. Its high sample recovery rate is especially important for diagnostic testing. In addition, flocked swabs are used for cleaning electronics, household, automotive and laboratory applications.

Sponge swabs: Sponge swabs are more commonly used for the collection of liquid samples, e.g. for oral, nasal or other secretions. In environmental monitoring, sponge swabs can also be used for microbial sampling for water quality testing. In the medical field, sterile sponge swabs are widely used in operating and diagnostic rooms for cleaning and disinfecting patients' surgical sites, as well as for wiping and disinfecting medical devices.

In summary, flocked swabs and sponge swabs have their own characteristics in terms of material, structure, properties and application scenarios. The choice of swabs should be based on specific sampling needs and application scenarios.